Estimated Reading Time: 9 minutes

You’ve written the perfect code. Your algorithm is flawless. But your robot? It just sits there, lifeless. Here’s the truth: code provides the brain, but hardware provides the body.

In robotics, understanding how robot joints and actuators work is the difference between a theoretical marvel and a machine that actually moves. While software engineers focus on algorithms and neural networks, the physical reality of robotics depends on a fascinating interplay between “skeleton” (joints) and “muscles” (actuators) that translates digital signals into real-world motion.

Think about it this way: when you decide to pick up a coffee cup, your brain sends electrical signals, but it’s your muscles and joints that execute the movement. Robots work the same way. The microcontroller sends commands, but it’s the motors, linear actuators, and drive systems that bring those commands to life.

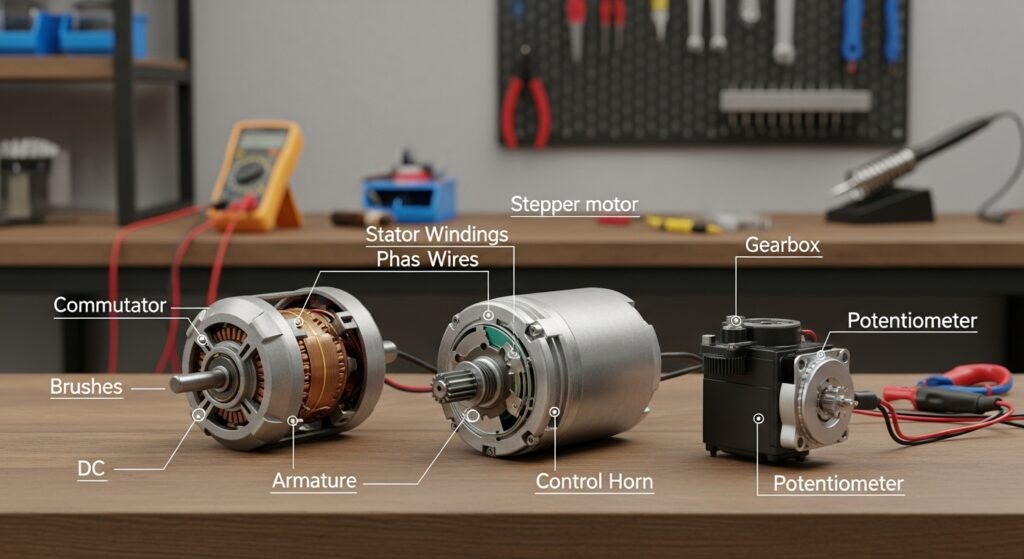

What are the main operational differences between DC, servo, and stepper motors? This question is at the heart of robotic hardware design. DC motors are fast and simple but often require gearing for precision. Stepper motors move in discrete steps for open-loop accuracy, which makes them ideal for 3D printers. Meanwhile, servo motors utilize sensors and controllers to maintain precise angles, making them the gold standard for robotic arms.

💡 Pro Tip: When selecting actuators, always consider the trade-off between speed, precision, and torque. No single motor type excels at all three simultaneously.

Robot Joints: The Points of Motion

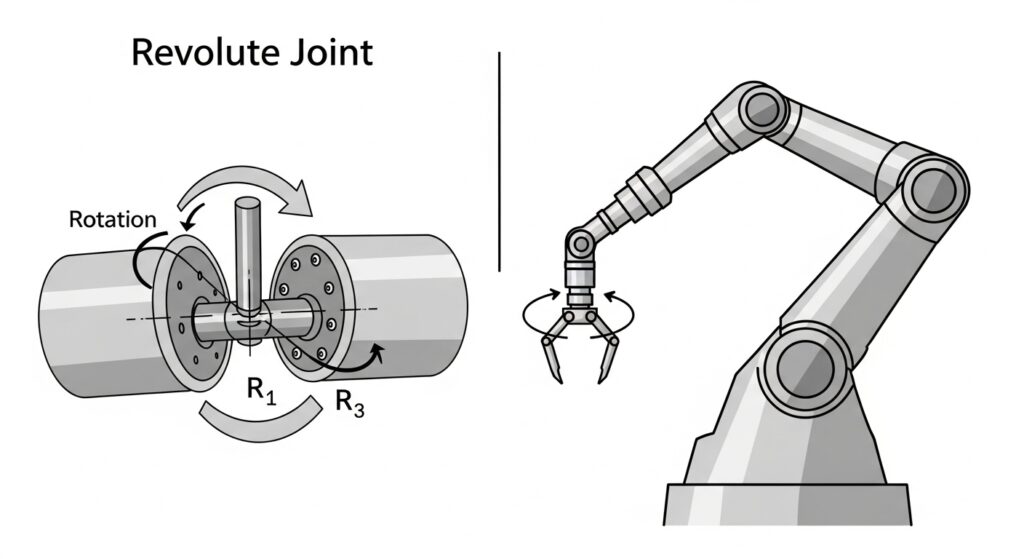

Just like in the human body, joints are the movable connections between the rigid segments (links) of a robot. They determine what engineers call “Degrees of Freedom” (DoF). This term simply means how many different ways the robot can move.

Revolute joints provide rotational movement, acting like a hinge at your elbow or a pivot at your wrist. These are by far the most common joint type in robotic arms. When you see a factory robot assembling a car, those smooth, sweeping movements? That’s revolute joints in action.

Prismatic joints allow for linear sliding movement. They extend or retract parts of the robot, similar to a drawer slide or a hydraulic piston. Picture a robot arm reaching forward to grab an object. That straight-line extension motion comes from a prismatic joint.

Moreover, the combination of these joint types determines the robot’s workspace. A robot with six revolute joints can reach any position and orientation within its range, while adding prismatic joints extends that reach even further.

The types of robot joints you choose directly impacts your robot’s capabilities. A painting robot needs different joint configurations than a surgical robot. Understanding this relationship is crucial for any robotics project.

Actuators: The Muscles Behind the Movement

Actuators are devices that convert energy (electrical, hydraulic, or pneumatic) into mechanical force. They drive the joints and make movement possible. Without actuators, your robot is just an expensive sculpture.

Electric Motors: The Standard Choice

DC motors offer continuous rotation and simplicity. They’re fast and reliable, perfect for wheels, fans, or any application requiring constant spinning. However, they rarely work alone in precision robotics. Why? Because they spin too fast with too little control for delicate tasks.

In my work with Autonomous Agentic AI and robotics simulation, bridging the “Sim2Real” gap is a constant challenge. While our machine learning models often assume ideal joint behavior, the physical reality of actuator backlash introduces noise that the agent must learn to filter. We often have to model the specific torque curves of servo motors within our training environments to ensure the neural networks generate control policies that actually transfer to the physical hardware.

Stepper motors move in discrete “steps,” typically 1.8 or 0.9 degrees per increment. This stepping action allows for open-loop control, meaning you don’t need sensors to know the motor’s position. Count the steps, and you know exactly where you are. This makes stepper motors incredibly popular for 3D printers and CNC machines. However, they’re less smooth for continuous motion tasks like robotic arms.

Servo motors represent the gold standard for robotics applications requiring precision. They combine a motor with a sensor (encoder) and a controller circuit to move to a precise angle and hold that position. Furthermore, they provide feedback, constantly adjusting to maintain the exact position you commanded.

When you program a servo motor to move to 90 degrees, it doesn’t just spin and hope for the best. It actively monitors its position and corrects any deviations. This closed-loop control makes servos essential for robotic arms, humanoid robots, and any application where position accuracy matters.

📈 Pro Tip: Servo motors typically operate in the 0-180 degree range for standard models, but continuous rotation servos and industrial servo systems can rotate fully 360 degrees while maintaining positional feedback.

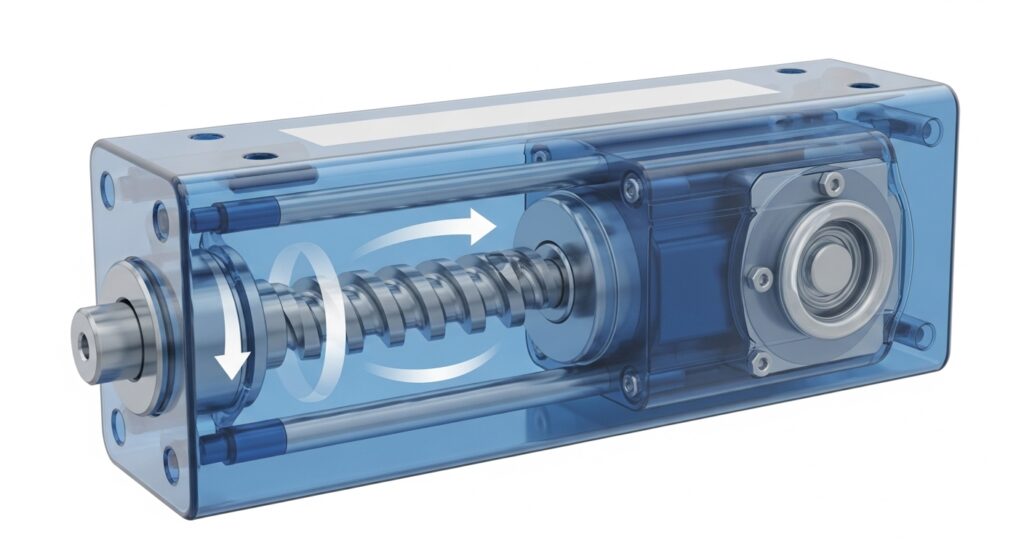

Linear Actuators: Straight-Line Power

Linear actuators convert the rotational energy of a motor into straight-line motion. A common mechanism involves a lead screw or ball screw. As the motor spins the screw, a nut travels up and down the shaft, pushing or pulling the load.

These actuators are perfect for applications requiring extension and retraction. Think of a robot leg extending to step forward, or a gripper arm reaching toward an object. The mechanics of linear actuators involve converting rotary motion into linear force with impressive efficiency.

Fluid Power: Heavy Duty and Fast

What are the distinct advantages of using pneumatic and hydraulic actuators over electric options? The answer lies in power density and speed.

Hydraulic actuators use pressurized oil to generate motion. They’re extremely strong, offering high force-to-weight ratios that electric motors can’t match. Boston Dynamics’ early Atlas robot relied on hydraulics for its incredible strength and dynamic movement. However, hydraulics come with drawbacks: they’re messy, require pumps and reservoirs, and need regular maintenance.

Pneumatic actuators use compressed air instead of oil. They’re very fast and have a natural “springiness” or compliance that makes them ideal for grippers or simple pick-and-place machines. The air compresses slightly under load, creating a cushioning effect that prevents damage when the robot encounters unexpected resistance.

Nevertheless, both fluid power systems are bulky and complex, making them less suitable for hobby projects or compact robots. They shine in industrial settings where raw power and speed matter more than portability.

🗣️ Pro Tip: Pneumatic systems respond faster than hydraulics because air compresses more easily than oil, but hydraulics deliver more precise control and greater force.

Drive Systems: Transmission and Torque

Here’s a fundamental problem in robotics: motors often spin too fast with too little torque (turning force) to move a heavy robot arm directly. A typical DC motor might spin at 10,000 RPM but struggle to lift even a small weight. Drive systems act as the transmission to solve this issue, reducing speed while multiplying torque.

Gear Reducers: The Torque Multipliers

Gear reducers decrease the motor’s speed while increasing its torque. The relationship is direct: if you reduce speed by 10x, you increase torque by roughly 10x (minus some efficiency losses).

Planetary gears represent a compact and efficient gear reducer design. These systems use a central “sun” gear surrounded by multiple “planet” gears, all contained within an outer ring gear. This design distributes the load across multiple gear teeth simultaneously, allowing for high torque in a small package. You’ll find planetary gears in wheel hubs, robot shoulders, and anywhere space is limited but torque is needed.

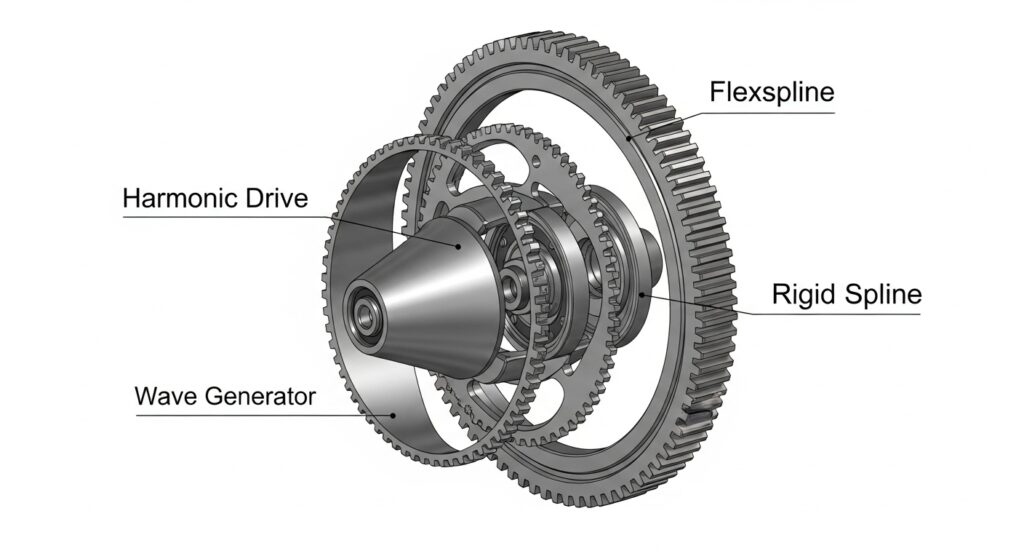

Harmonic Drives: Zero-Backlash Precision

How do drive systems like gear reducers and harmonic drives differ in providing torque and precision? Harmonic drives represent a specialized gear system that uses a flexible metal cup that deforms to engage teeth.

Here’s why harmonic drives matter so much in high-precision robotics: they have zero backlash. Backlash is the “slop” or wiggle in a joint when you change direction. In regular gears, there’s always tiny gaps between teeth. When the motor reverses, those gaps create dead zones where nothing moves. For a robot trying to position something with millimeter accuracy, this is unacceptable.

Harmonic drives eliminate this problem through their unique design. Additionally, they achieve extremely high reduction ratios (often 100:1 or more) in a remarkably small package. This allows robots to be precise down to the millimeter while maintaining compact joint designs.

The trade-off? Harmonic drives are expensive and require careful maintenance. But for applications like surgical robots, precision manufacturing, or space exploration, they’re often the only option.

Direct Drive: Safety Through Compliance

In contrast, some modern “quasi-direct drive” robots take a different approach entirely. High-torque motors connect directly to the limb without high-ratio gears. This makes the robot “back-drivable,” meaning if you push it, the motor spins freely.

Why does this matter? Safety and interaction. When a robot with harmonic drives encounters resistance, it keeps pushing with full force. A direct-drive robot yields to the touch, making it safe for working alongside humans. Robotic dogs and collaborative robots (cobots) increasingly use this approach.

However, direct drive requires more sophisticated motors and control systems. The motor must provide high torque at low speeds, which typically means larger, more expensive motors. The control algorithms must also be more advanced to maintain stability without the mechanical advantage of gears.

You can learn more about robot power and drive systems to understand these trade-offs in depth.

Selecting the Right Hardware: A Practical Guide

How robot joints and actuators work together determines what your robot can accomplish. Here’s a practical selection guide:

Need fast spinning? Choose a DC motor. They excel at continuous rotation for wheels, fans, or propellers. Control them with an H-bridge motor driver for bidirectional movement and speed control through PWM signals.

Need precise angles? Select a servo motor. Perfect for robotic arms, camera gimbals, or any application requiring exact positioning. Servo motors hold their position even under load, making them ideal for applications where stability matters.

Need high-precision coordinates? Pick a stepper motor. The discrete stepping action provides excellent position accuracy without requiring expensive encoders. Consequently, stepper motors dominate in 3D printers, CNC machines, and automated manufacturing.

Need heavy lifting? Consider hydraulics. When force matters more than precision or compactness, hydraulic actuators deliver unmatched power density. Industrial robots routinely use hydraulics for lifting, pressing, and moving heavy payloads.

Need speed with compliance? Think pneumatics. The natural springiness of compressed air makes pneumatic actuators perfect for grippers and handling delicate objects. They’re fast, safe, and relatively simple to control.

The key is understanding your robot’s job and picking the actuator that fits best. There’s no universal “best” motor, only the best motor for your specific application.

💡 Pro Tip: Always calculate your torque requirements before selecting motors. A common beginner mistake is choosing motors based on speed alone, then discovering they can’t actually move the robot’s weight.

Bringing It All Together

Understanding how robot joints and actuators work moves you from theory to practice. The skeleton provides structure and defines possible movements through robotic degrees of freedom. The muscles (actuators) provide the force. The drive systems optimize that force for the specific task.

In robotics simulation, we often discover that the theoretical perfect solution breaks down when confronted with real hardware limitations. The discrete stepping nature of motors introduces noise. Gear backlash creates positioning errors. The flexibility in drive systems adds compliance we didn’t account for in our models.

This is why hardware knowledge is so critical. You can’t build reliable robots without understanding the physical components that execute your commands. Software provides the intelligence, but hardware provides the capability.

Ready to see these components in action? Watch this comprehensive video breakdown demonstrating the physical differences between servos, steppers, and DC motors in a workshop setting. Seeing the actual hardware helps solidify these abstract concepts into practical knowledge.

The future of robotics depends on engineers who understand both software and hardware. As machine learning and AI make robots smarter, the physical systems that execute those decisions become even more critical. After all, what good is perfect planning if your actuators can’t execute the movement accurately?

Start experimenting with different motor types. Build small projects. Make mistakes. Learn what works and what doesn’t. That hands-on experience with how robot joints and actuators work will prove invaluable as you tackle more ambitious projects.

The hardware brings your robot to life. Master it, and you’ll transform those lines of code into machines that truly move.